3D Printing

3D Printing

I have an Ender3 FDM printer that I use for various projects.

Minifigures

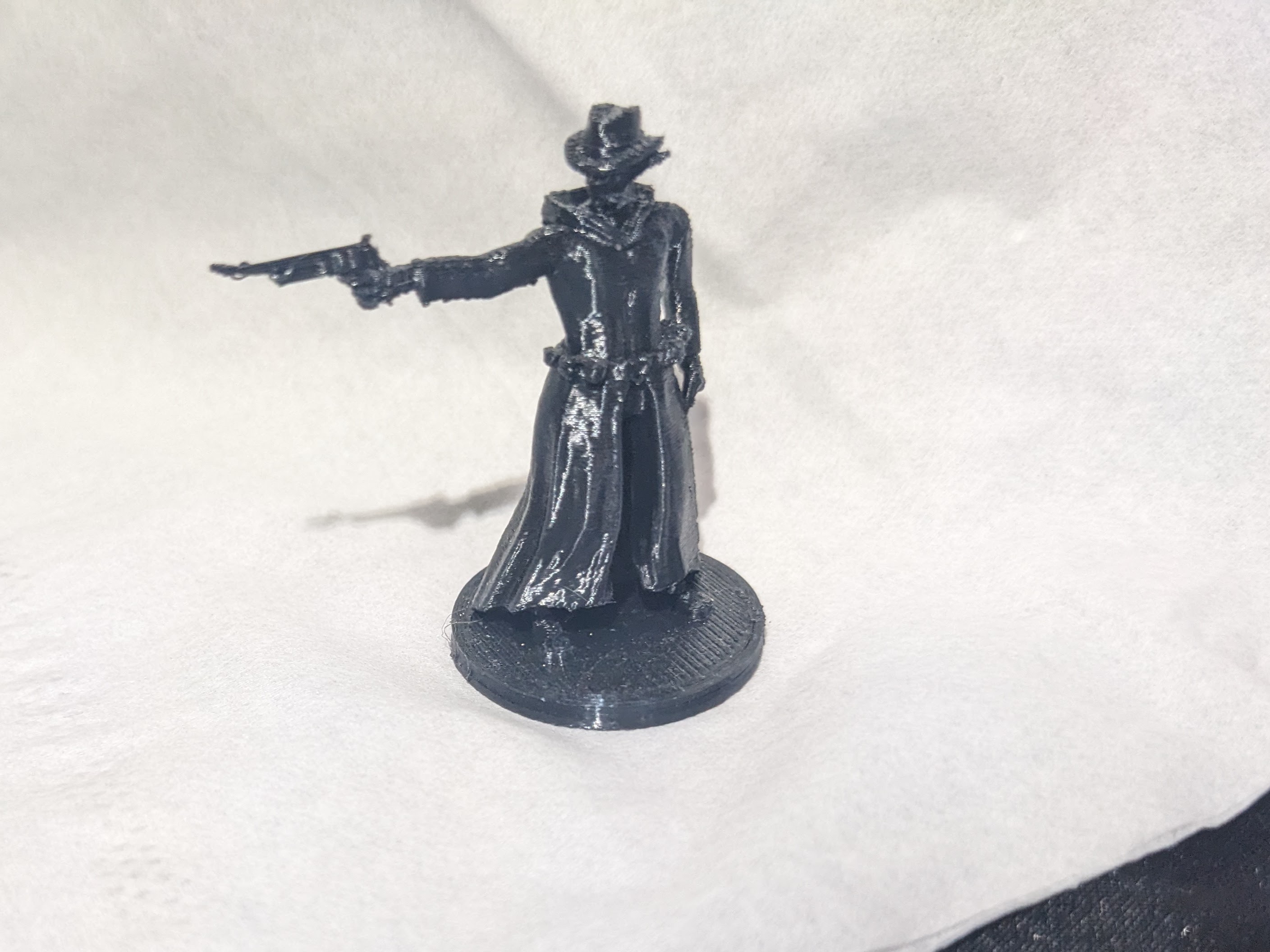

For table top role playing games, such as D&D, I print minifigures for my housemates and I to use. While 3D printed minifigures are relatively common, they’re mostly done in SLA/Resin as it has much higher fidelity to capture detail on minis.

Having only an FDM printer, I spent plenty of time tweaking various settings in order to make sure minis printed correctly, including finicky pieces such as weapons, staffs, and fairy wings.

I mainly changed support settings, increasing or decreasing support distance from the model, changing support structure, and so on. Too little support made the model fail to print, but too much support would trap the model and make it break during removal.

The lower two images are of a Harengon ranger before print setting tweaks, and the upper two images are after print setting tweaks.

Here are some other models I printed:

Bracelet

I wanted to create a tagged bracelet for use in a live action role playing game, and had access to chain and clasps. This project was severely limited in time: I started the project half an hour before needing to leave for the game. I CADded the tag I wanted to make in OnShape, then started a print, which was supposed to take five minutes. Halfway through the print I realized I had misjudged the size of tag I wanted, and so I adjusted the CAD and started a new print as soon as the previous had finished. I threaded the tag onto the chain and attached a clasp; the finished project from raw material to bracelet took almost exactly half an hour.

Phone Holster

This project is a phone holster designed to hold my phone on my hip. I CADded the plastic piece in OnShape, then printed it on the FDM printer.

Then, I attached chain and clasps so that it would fit around my body.