Yo-Yo Manufacture Project

The class 2.008: Design and Manufacturing II requires students to spend a semester designing and then manufacturing 50 identical yo-yos. The class taught manufacturing techniques including CNC milling, thermoforming and injection molding.

While working on the design of the yo-yo, I drew the images which were printed onto the thermoformed plastics or transformed into the 3D textures in the injection molded parts.

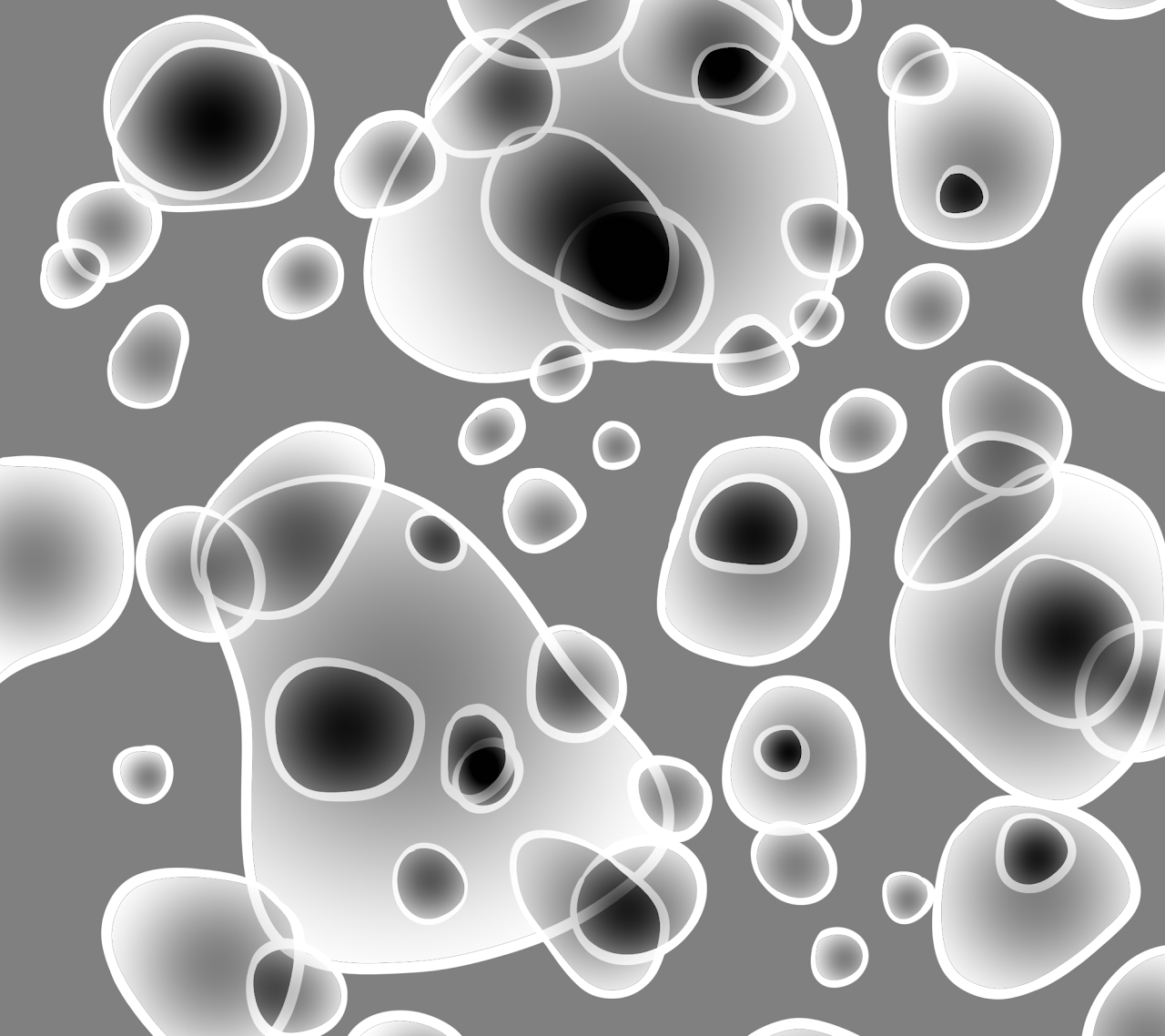

The process of texturing the parts was fairly interesting. First I drew a design in greyscale:

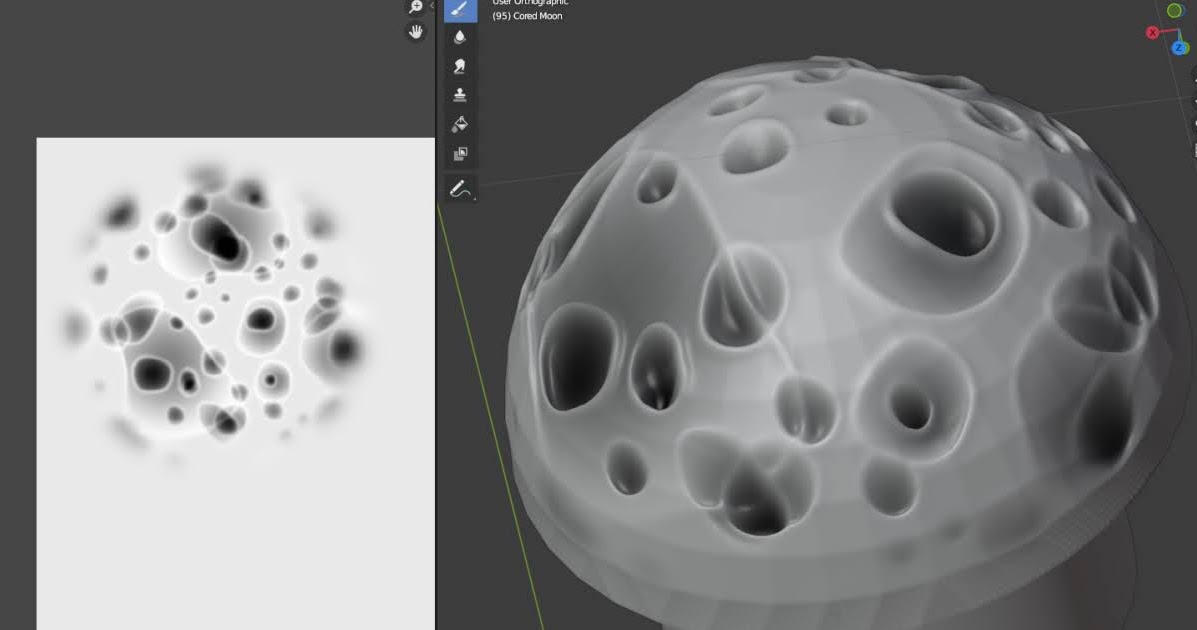

Our team imported my grayscale designs into blender, then mapped the values into height values to alter the shape of the 3D object.

Provided only the z-values were altered across the surface of the sphere, the part was still machineable on a 3-axis CNC mill.

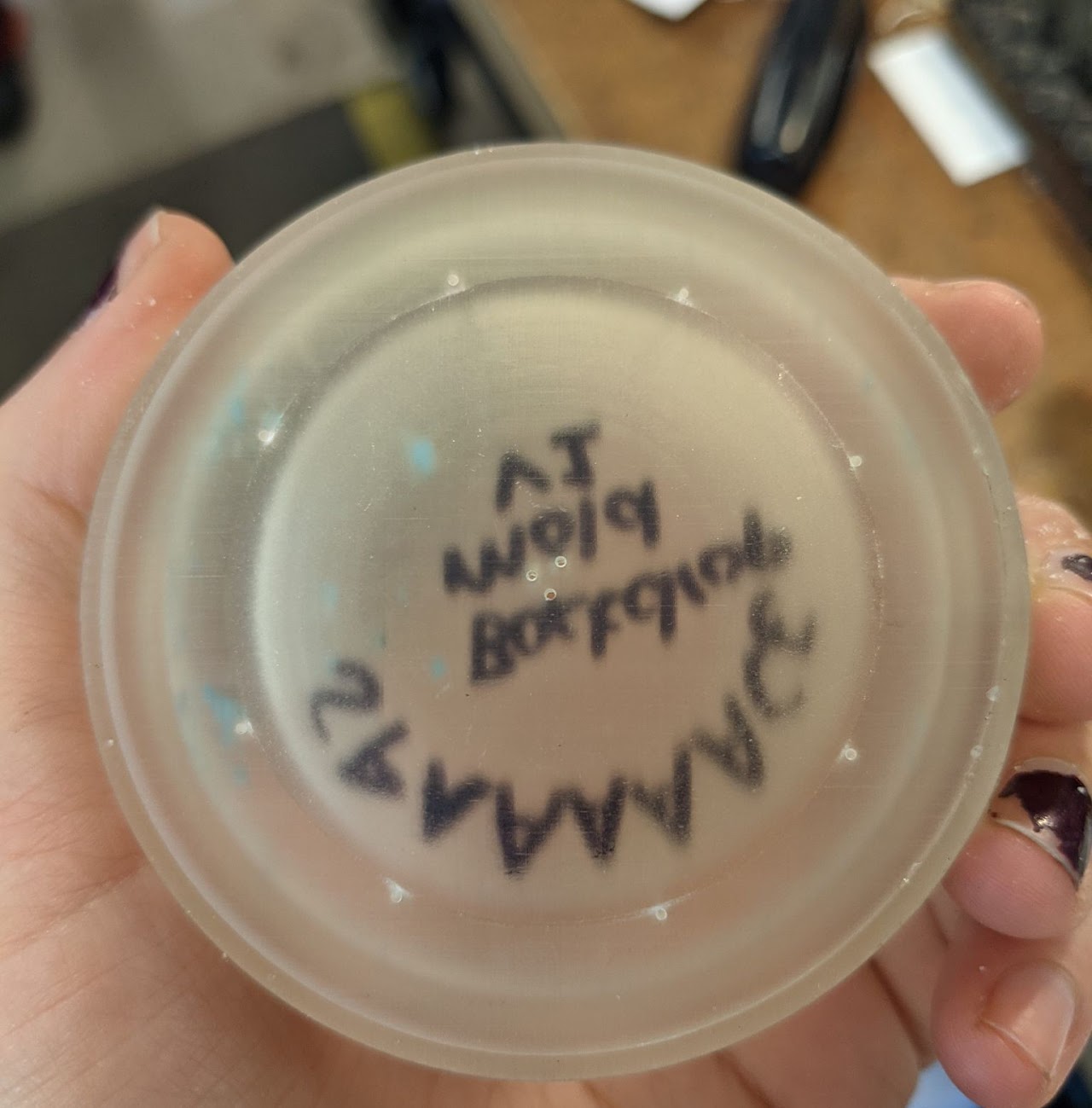

Negatives of each injection molded part were milled from a block of aluminum, then we used the injection molder to create the parts. I participated in the milling and injection molding, as well as analysing the finished plastic parts and measuring them to determine if the press-fit was secure. We ended up re-milling the negatives in order to account for shrinkage in the plastic part, which led to very well-fitted yo-yos.

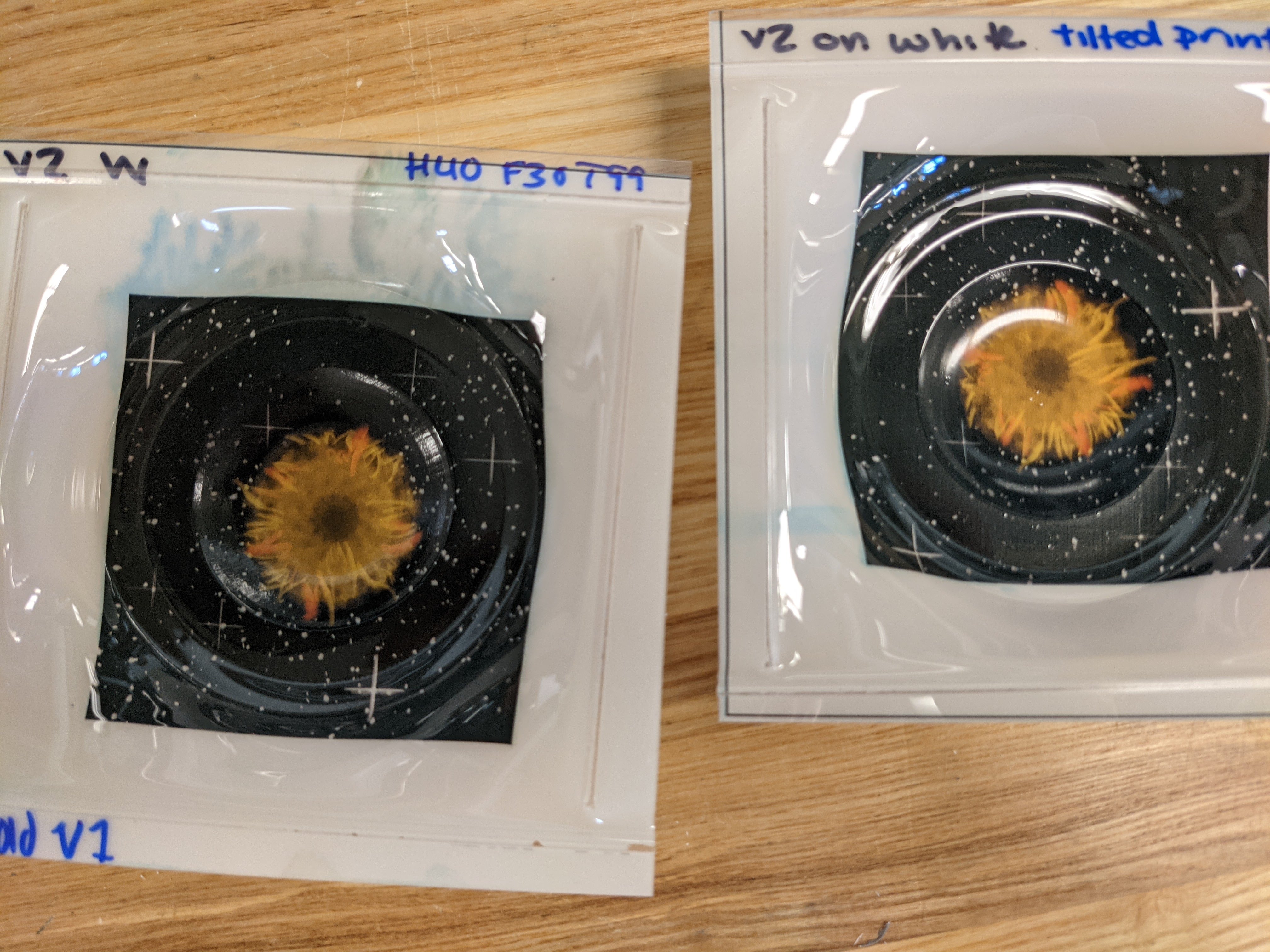

I also did design for the thermoform parts, both drawing the background image and creating the resin-printed thermoform negatives.

The sun background image was printed onto a clear sheet of plastic, after which I used the thermoforming machine and punch to shape the plastic pieces for assembly. For the ink to not crack while the plastic is stretching, it first needed to be coated with a setting spray.

These were the thermoformed printed pieces, in the middle of testing the coating:

After completing the requisite 50 yoyos, our team joined the manufacturing challenge and completed another 59 more in the span of nine total lab hours.